Colour Fastness and Durability

Weathering or lightfastness:

Why is this distinction important?

The difference between weatherfastness and lightfastness.

The resistance to sunlight behind filtered glass is known as lightfastness (ISO 4582). This rating is pertinent for articles to be used indoors only. Samples are exposed in a Xenon Arc machine, with 8 blue wool scale samples. These are dyed sections of cloth known to fade at a known rate. The light source simulates actual daylight but at around 5 times the energy level to speed up the process. The test is concluded when the blue wool (1-8) of fade level compared with ISO grey 1-5 (ISO 105 A02) where scale 3 has occurred. The rating is given as:

|

Blue Wool Rating |

Lightfastness |

Visual Representation |

|

8 |

Outstanding |

|

|

7 |

Excellent |

|

|

6 |

Very Good |

|

|

5 |

Good |

|

|

4 |

Moderate |

|

|

3 |

Fair |

|

|

2 |

Poor |

|

|

1 |

Very poor |

Although these ratings cannot be taken as absolute they do give a good indication of comparable expected values under given conditions.

A more stringent test of durability for a coloured material is that of exposure to actual outdoor conditions. This is described as Weatherfastness.

Samples may be exposed to actual outdoor performance in known climatic conditions or again be subjected to artificial weathering conditions in apparatus such as weatherometers.

Although there are several different types of machines available, the international standard (ISO4892-2) quotes a particular irradiance level and cycle to mimic more closely actual outdoor exposure; again at an accelerated rate. This is rated against the ISO grey scale. Other changes in the samples should also be noted, such as change of hue, gloss differences, darkening and chalking.

Importance of correct formulating to meet lifetime expectancy:

1: In order to stand a chance of meeting the criteria being requested.

2: to prevent the instigation of degradation due to free radicals attacking the polymer from within.

3: End effects when weatherability is an issue. Crazing, chalking, mechanical failure, Premature breakage, Failure to be recognizable.

Types of test:

Actual weathering with samples exposed in various climatic conditions.

Pros: how the article will perform when used in the end application

Cons: length of time to gain results.

Accelerated weathering tests:

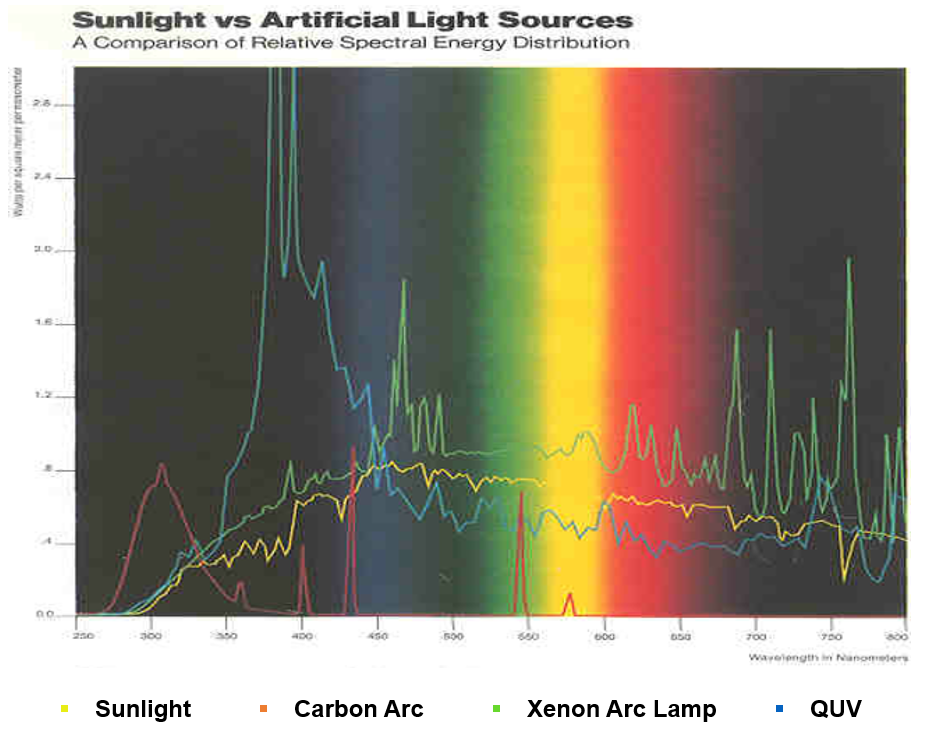

QUV – whilst being a quicker test to achieve results in comparison to the Xenon Arc and actual weathering; this type of test has no effect on the pigment and cannot be used to form an opinion of the weatherfastness of a pigment.

Rather this type of machinery tests the actual polymer system. It imparts irradiance between 295nm-400nm in the case of UVA 340 lamp with a peak emission of 340nm. Whereas 270nm-380nm in the case of UVB 313, peak emission of 313nm.

The latter bringing about shorter lengths of testing due to a more severe, shorter wavelength and UVA-340 lamps bring a good correlation to spectral energy distribution of noontime summer sunlight up to 380nm approx. Results obtained under this test these may be considered more meaningful than UVA-B.

However, in both cases, this is almost all in the non-visible area of the electromagnetic colour spectrum and more importantly the area of the spectrum that degrades plastics and the surface of coatings. But not of true relevance to pigment performance due to solar cut off. That is, as the wavelength distribution has no light in the visible or IR regions, the tests with these machines cannot differentiate between the effects of colour. That means that dark colours will be the same temperature as light, which in reality is when exposed to the sunlight.

Xenon arc – this type of apparatus offers a much closer correlation to natural sunlight providing the closest simulation of wavelengths to sunlight from UV (see image below) through visible and IR regions of the electromagnetic spectrum. They also provide relative humidity, rainfall, dew and varying temperature. They control the irradiance to ensure light intensity from the Xenon lamp is regulated/controlled during the cycles of the experiment.

With many weathering tests being 1000 hours at least the ability to control the cycle and monitor the lamp intensity is of vital importance to the meaning of the results and for comparison purposes.

The development team here at Prisma Colour will focus ideas to your design requirements when formulating your colour masterbatches and speciality compounds whether for thermoplastics, rubbers or silicones.

Use our revised colour match request forms to better meet your needs.

Contact us now to discuss your colour developments.

Register Your Interest

This is one part of a series of articles relating to colourant properties and design. We will expand on various topics in more detail in a separate articles. Please register your interest in receiving further details by entering your contact details below